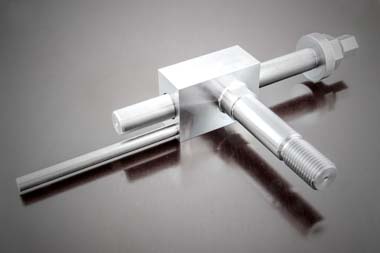

CNC MACHINING. PIECE AND SERIES PRODUCTION

We are a small family business with a tradition dating back to the year 1989.Our services

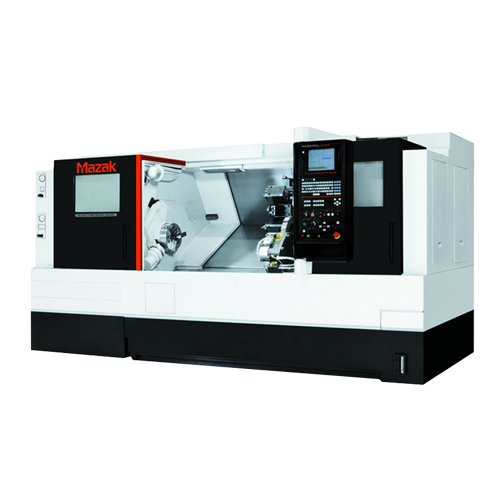

All the machining processes are carried out by our new CNC Mazak machines. On the basis of the submitted drawing files we can provide for piece and series production processing all kinds of steel, non-ferrous metals and plastics. We deal with production of single-purpose machines, clamping devices and spare parts for all kinds of machines. We maintain high quality machining and consider meeting deadlines for delivery to be number one priority. In cooperation with partners we also provide for heat treatment and surface finish.

WE USE THE FOLLOWING CNC TECHNOLOGIES AND MACHINES

QUICK TURN SMART 350

QUICK TURN NEXUS 200-II MSY

Hartford P.C. PRO1000

4 axis vertical milling centre. 24 tools, 20 bar cooling. Workpiece maximum size is

1000 x 500 x 500 mm. Including a 320 kg crane.

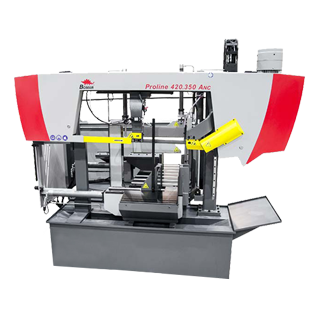

BOMAR PROLINE 420.350 ANC

SURFACE GRINDER

Prusa i3 + Multi Material 2S

Powerful second-generation 3D printer for printing up to five materials simultaneously.

QUALITY

Our technicians measure each piece by means of Mitutoyo measuring instruments with accuracy of +- 0.005 mm.

Contacts

Bc. Jan Kopún

Director and Production Manager

Phone: +420 777 863 014

Fax: +420 354 431 024

kopunovi@atlas.cz

OUR PLACE OF BUSINESS

CNC Kopún s.r.o.

Karlova 34 A, 350 01 Cheb, Czechia

IČ: 029 75 530

DIČ: CZ 029 75 530